Crack Sealing

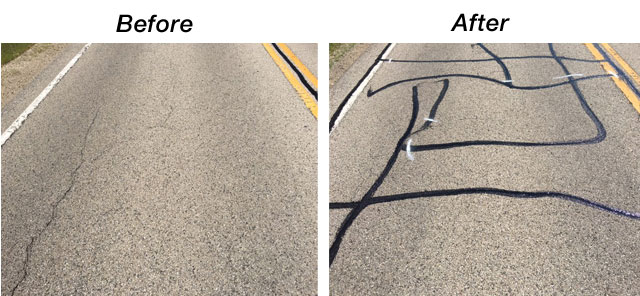

Many factors contribute to unfavorable performance results of pavement that is not well maintained. These forces include but are not limited to thermal expansion and contraction, freeze thaw cycles, traffic, weathering, and intrusion of incompressibles. Cracks should be addressed with the appropriate joint sealant meeting the specified performance criteria. In the industry crack sealing and crack filling are interchangeable terms and are referred either way.

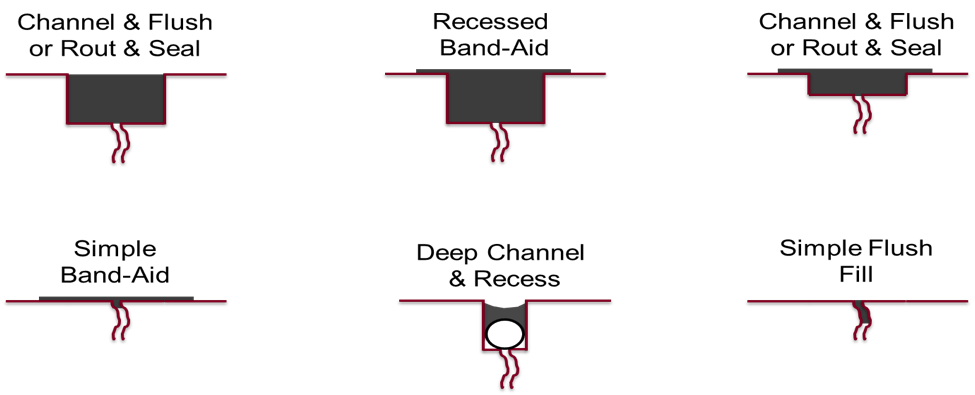

Rubberized Crack Sealing: SKC uses IDOT approved hot applied rubberized crack sealing products that meet or exceed ASTM D 6690 Type II. The crack sealing pavement maintenance procedure involves placement of specialized material into working cracks using unique configurations to reduce the intrusion of incompressibles into the crack and to prevent intrusion of water into the underlying pavement layers. Working cracks are defined as those that experience significant horizontal movements, generally greater than about 2 mm (.1 in.). * Typical sealing configurations are shown below.

Crack sealing can add years of additional life to pavement.

Fiber Modified Asphalt Crack Sealing: is a field blended polymer modified hot applied crack sealing product. The blend consists of an 8% minimum Polypropylene fibers and asphalt cement that meets or exceeds IDOT specifications. Fiber Modified Asphalt crack sealing requires specialized equipment to blend an 8% min. Polypropylene fiber content. The first picture below shows Polypropylene Fibers and the second shows asphalt cement. The third picture below shows the common sealing configuration called overband. Resulting in a product with proven performance in the industry.

Through never-ending research, development, and field testing, we constantly look for ways to incorporate the most recent technological improvements into our vast line of sealants.